Weeks before Thanksgiving, a national provider of turkeys suffered a freezer-related fire that destroyed the facility, devasting the business. Nearly one hundred thousand frozen turkeys, ready for shipping, were lost in one night.

Digital Transformation

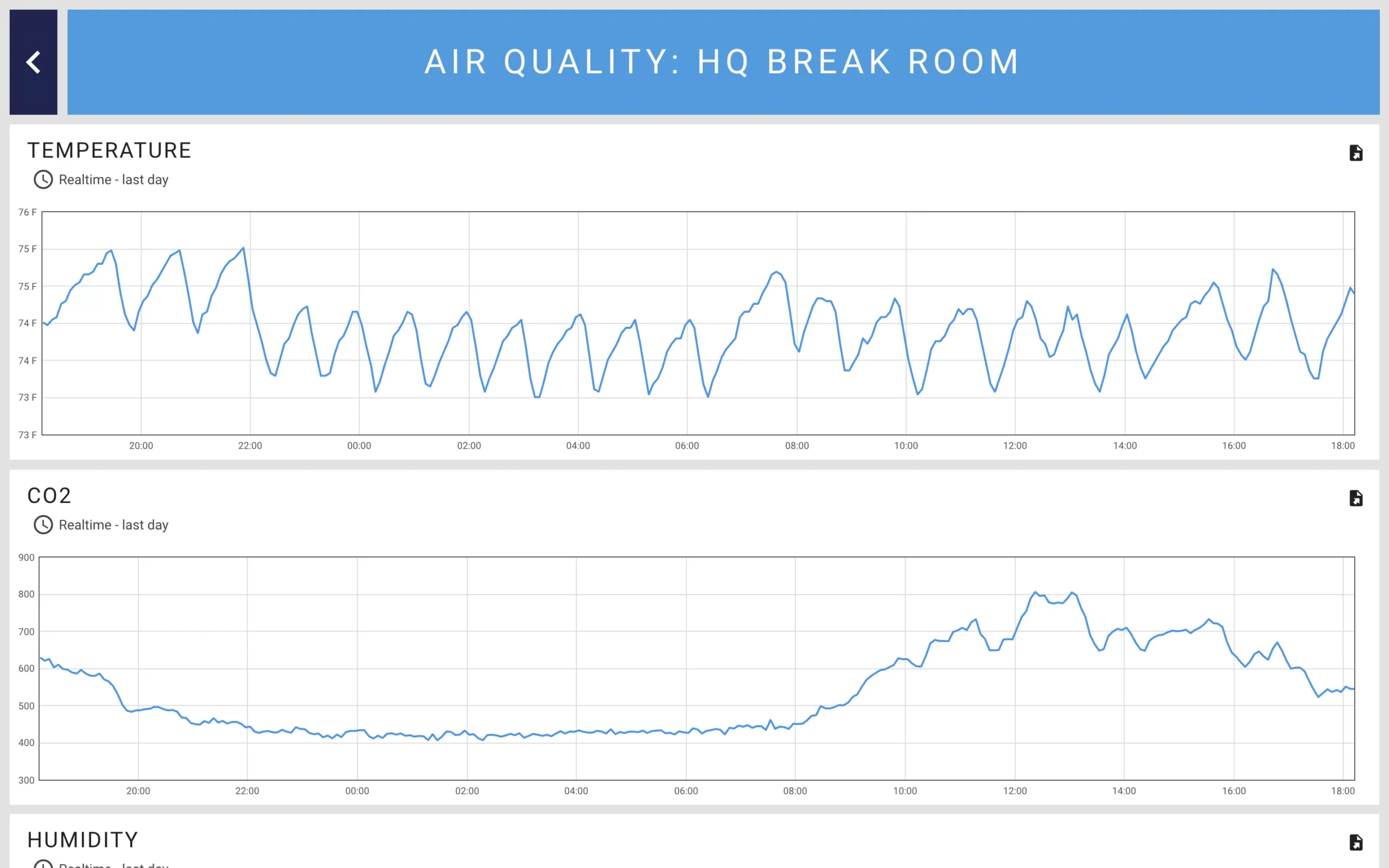

Automated digital sensing and recording replaced manual methods

Industrial Grade IoT Sensors

The IoT temperature sensors were rugged, lightweight, and wireless

Instant Alerts

DeepInsights™ alerted whenever any sensors were out of range

30-Day Logs

Readings were archived, and were exportable for further analysis

Cutting Through the Noise

You want to be notified of what is trending badly, not that everything is ok

Focusing on the Core Business

Monitoring freezer coil temperatures is not part of anyone’s core business, so it must be automated

Remote Monitoring

From a distance, digital notifications must replace manual readings, notes on paper, and phone calls

The solution directly addressed the immediate need - the continuous remote monitoring of freezer coils with immediate alerts to avoid future incidents. But it also laid down the platform for solving other challenges that arise over time including:

Each of the freezers’ multiple coils has its own sensor. The wireless sensors were small and battery-powered, with an average battery life of around 10 years. As with all sensors, battery life is a trade-off between measurement frequency and alert response time. By recording temperatures every 60 seconds, the customer maximized battery life while having plenty of time to respond to abnormal fluctuations, as shown below.

In just 30 minutes, DeepInsights™ detects a sudden rise in one coil taking it beyond the usual 8°F limit, sending a mass notification to staff

"We now have full control and visibility of our assets across the entire geography and can anticipate and intercept developing threats before they become real problems”

- Friant Water Authority