Reach Your Environmental Sanitization Goals

Research shows people and businesses have a false sense of security when it comes to germs.

1.2M

Gym showers hold 1.2M germs in every 6x6 square inch of space

1 in 25

The ratio of patients catching something while in a healthcare facility

20

The number of students who pick up something per school, every day

Advantages & Benefits

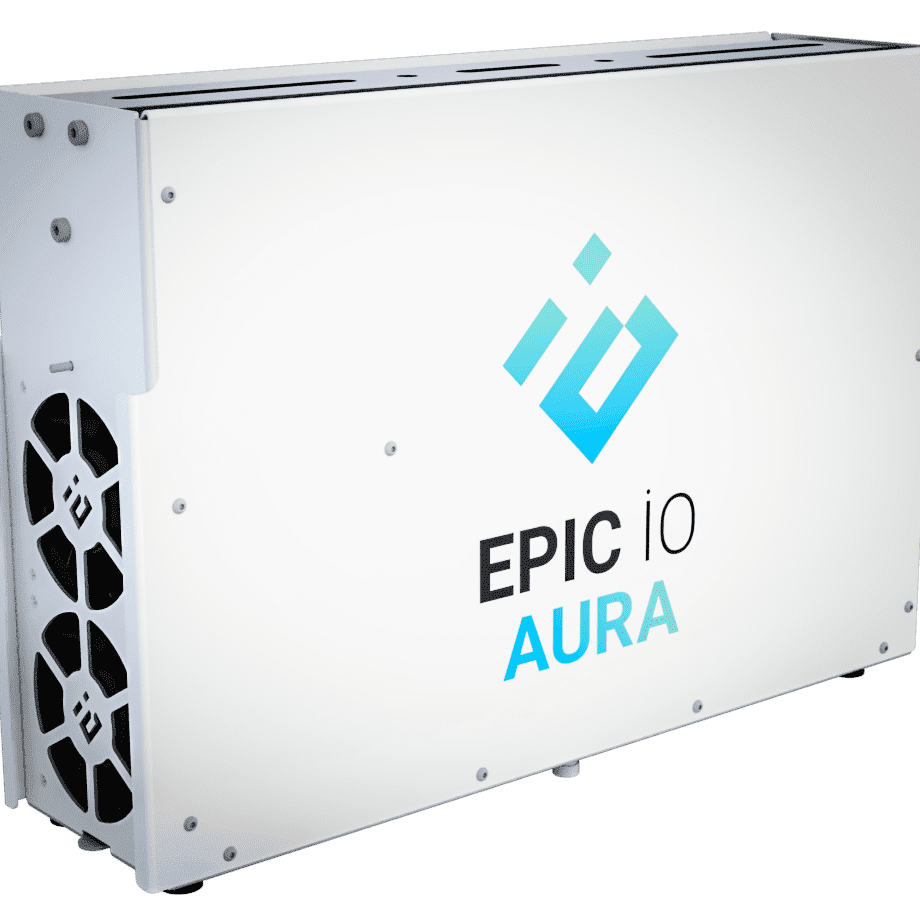

Disinfect. Sanitize. Deodorize.

It’s impractical to disinfect every square inch of a room. EPIC iO AURA™ transforms the air to disinfect every surface it touches.

Reaches Everywhere

It’s impractical to disinfect every square inch of a room. EPIC iO AURA™ transforms the air to disinfect every surface it touches.

Decontaminating Rental Units

Cycling misused properties is painful.

Looks Clean

Definitely NOT Clean

One Unit. Multiple Uses.

Fully autonomous unit designed for versatile spaces.

Reduces Foodborne Illnesses

Destroys microorganisms that cause illnesses and spoil food.

Kills the Stink

Removes odors from cigarettes in just 2 hours.

Addressing the Broader Challenges of Enterprise Biosecurity

EPIC iO AURA leverages Artificial Intelligence (AI) and the Internet of Things (IoT) to kill the microorganisms that seek to harm us and our food supply. It is the only disinfection appliance of its kind to incorporate sensors to track delivered dosages and effectiveness which can be tracked over time to verify improvement.

Loved by the World’s Best Brands

Discover how EPIC iO customers created safer environments.

Arenal Manoa Resort Hotel and Hot Springs

The EPIC iO Point of View

Check out the latest industry trends, outlook, and best practices for safer environments.